- Parts Online Pte.Ltd.

- Four-Row Tapered Roller Bearings TQITS Nachi Gear Pump Four Row Tapered Roller Bearings

- Home

- Product Categories

- Four-Row Tapered Roller Bearings TQITS

- Nachi Gear Pump

- Four Row Tapered Roller Bearings

- TNASWH Two-Row Tapered Roller Bearings

- Cylindrical Roller Bearing

- Tapered Roller Bearings Double-Row TNA

- Full Row Of Cylindrical Roller Bearings

- Four-Row Cylindrical Roller Bearing Inner Ring Outer Assembly

- Tapered Roller Bearings Double-Row Type TDO

- Vickers Gear Pump

- Four Row Cylindrical Roller Bearings NSK

- Oilfield Bearings

- NSK Roll Bearings For Mills

- Thailand Bearing Authorized Dealer

- Rolling Bearings For Steel Mills NSK

- NSK Double Row Tapered Roller Bearings

- NTN Multi-Row Roller Bearings

- TIMKEN Sealed Roll Neck Bearings

- Vickers Piston Pump

- Mud Pump Bearings

- TP Thrust Cylindrical Roller Bearing

- Slewing Ring

- Tokyo Keiki Vane Pump

- Oilfield Bearings

- Rexroth Pump

- Daikin Vane Pump

- Parker Vane Pump

- Thrust Bearings

- Daikin Rotor Pump

- Maintenance Products Air Driven Oil Injector

- Indonesia Bearing Authorized Dealer

- Coupling Mounting And Dismounting Kit

- Singapore Bearing Authorized Dealer

- Four-Row Cylindrical Roller Bearings

- Mud Oilfield Pump Bearings

- TTHD Thrust Tapered Roller Bearings

- Double Row Cylindrical Roller Bearings

- Land Drilling Rig Bearing

- Heavy-Duty Needle Roller Bearings

- Heavy-Duty Shaker Screen Spherical Roller Bearings

- Four Row Cylindrical Roller Bearings NTN

- Spherical Roller Bearings NSK

- NSK Crossed Roller Bearings

- Single Row Tapered Roller Bearings Inch

- Tapered Roller Bearings Double-Row Spacer Assemblies

- Thrust Cylindrical Roller Bearings

- Thrust Spherical Roller Bearings

- Nachi Piston Pump

- Oil Industry Drilling Bearing

- DTVL Angular Contact Thrust Ball Bearing

- Four Point Contact Ball Bearings

- Cylindrical Roller Thrust Bearing NSK

- Yuken Hydraulic Component

- Double Row Full Complement Cylindrical Roller Bearings

- Main Pump

- Full-Complement NCF Cylindrical Roller Bearings

- Oilfield Mud Pump Bearings

- Malaysia Bearing

- NSK Single Direction Thrust Ball Bearings

- Oil Seal SKF

- NSK Tapered Roller Thrust Bearing

- Single Row Cylindrical Roller Bearings

- Double Row Angular Contact Ball Bearings

- Thrust Spherical Roller Bearing

- Spherical Roller Bearing

- Deep Groove Ball Bearings

- Full Complement Tapered Roller Thrust Bearing

- Screwdown Systems Thrust Tapered Roller Bearings

- Cylindrical Roller Bearings One-Row Standrad Series

- FAG محامل

- SKF محامل وحدات

- محامل كروية من رولز NSK

- صف مزدوج تناقص الأسطوانة المحامل NSK

- محامل عادي SKF

- SL Type أسطواني محامل ل شيفيس NTN

- فحوى الكرات

- فحوى الأسطوانة المحامل

- الكرة الاخدود العميق محامل

- المحامل الدفعية NSK

- محامل منتجات هندسية skf

- SKF محامل ختم

- محامل متعددة الصف NTN

- رول محامل للمطاحن NSK

- المحامل الدفعية NTN

- اتجاه واحد الصدر محامل الكرة NSK

- محامل أسطوانية مزدوجة-رو NSK

- الكرة الاخدود العميق محامل

- إبرة محامل

- إبرة محامل

- فحوى الكرات

- محامل للتطبيقات الخاصة NTN

- SKF تحمل الملحقات

- FAG محامل

- محامل وحدات

- محامل الإسكان

- محامل حقول النفط

- محامل عادي

- أربعة رو المحامل المدبب NSK

- الزاوي الاتصال الكرات

- محامل القسم رقيقة KAYDON

- محامل SKF

- أربعة أسطواني محامل أسطواني NSK

- محامل اسطوانية أسطوانية NSK

- Rodamientos de agujas

- Rodamientos

- Rodamientos de una hilera de rodillos cónicos pulgadas

- Rodamientos de Bolas Autoalineables

- Rodamientos de Rodillos Cilíndricos

- Rodamientos de rodillos esféricos

- Rodamientos de Rodillos Cilíndricos

- Rodamientos de dos hileras de dos hileras de rodillos cónicos (serie de pulgadas)

- Unidades de rodamiento

- Soportes para rodamientos

- Parker PAVC Piston Pump

- Rexroth AA4VSO

- TDIK Rodamientos de rodillos

- Rodamientos de rodillos cónicos

- Rodamientos de rodillos cónicos

- Rodamientos de bolas de contacto angular

- Rodamientos de dos hileras de bolas de contacto angular

- Rodamientos de dos hileras de rodillos cónicos dobles pulgadas

- Rodamientos de rodillos cónicos

- Rodamientos de Rodillos Cilíndricos

- Rodamientos de manga

- Rodamientos de rodillos cónicos

- Rodamientos de rodillos esféricos

- Rodamientos de agujas

- Rodamiento de rodillos esféricos de empuje

- TTDFLK, TTDW And TTDK Rodamientos

- Rodamientos de Rodillos Cilíndricos

- Completo rodillo cónico Rodamiento de empuje

- Rexroth A10VSO

- Rodamientos rígidos de bolas

- Accesorios Para Rodamientos

- Rodamientos de bolas de precisión de precisión

- Rodamientos de rodillos cónicos de doble hilera TDI TDIT

- Rodamientos de bolas de cuatro puntos de contacto

- Rodamientos dobles de dos hileras de rodillos cónicos TDI

- TOKYO-KEIKI Vane Pump

- Rodamientos de dos hileras de rodillos cónicos dobles

- Rodamientos de bolas de precisión

- Sellos radiales de eje

- Rodamientos de Rodillos Cilíndricos

- Screwdown Systems Thrust Tapered Roller Bearings

- YUKEN Piston Pump

- SKF Unidades de rodamientos

- Rodamientos de cuatro hileras de rodillos cónicos

- Rodamientos de una hilera de rodillos cónicos

- Rodamientos de equipos de fluidos de perforación

- DTVL Rodamiento de bolas de contacto angular

- Rodamientos de rodillos cilíndricos de empuje

- Parker PVP Piston Pump

- Unidades de rodamiento

- Rodamientos de bolas de contacto angular

- Rodamientos De Bolas De Contacto Angular Type TVL

- TOKYO-KEIKI Piston Pump

- Rodamientos axiales de rodillos de empuje

- Rodamientos de agujas

- Rodamientos Plásticos Plásticos

- RODAMIENTOS PLÁSTICOS

- TDO Rodamientos de dos hileras de rodillos cónicos

- Rexroth A15VSO

- Rodamientos de agujas

- Roulements à billes à contact angulaire

- Roulements à rouleaux cylindriques

- Double-Row Tapered Roller Bearings NSK

- TTHD Thrust Tapered Roller Bearings

- Roulements à rouleaux cylindriques

- YUKEN Piston Pump

- Roulements à rouleaux cylindriques

- TTHDFLSA Thrust Tapered Roller Bearings

- Roulements à billes à contact angulaire

- Roulements à rouleaux coniques

- Roulements à aiguilles

- Spherical Roller Bearings NSK

- Thrust Cylindrical Roller Bearings

- TTHDFL Thrust Tapered Roller Bearing

- Roulements à aiguilles

- TPS Thrust Cylindrical Roller Bearing

- Four-Row Cylindrical Roller Bearings

- Roulements à rouleaux cylindriques

- Roulements rigides à billes

- unités de roulement

- Les roulements à rouleaux de confiance

- Roulements à billes à contact angulaire

- Heavy-Duty Needle Roller Bearings

- Roulements à billes

- TP Thrust Cylindrical Roller Bearing

- Roulements à billes auto-alignés

- Roulements à billes de poussée

- Cylindrical Roller Bearings Two-Row

- Single-Row Tapered Roller Bearings NSK

- Roulements à billes à rainure profonde

- Roulements à aiguilles

- Roulements à rouleaux sphériques

- Roulements à billes à rainure profonde

- Roulements à billes à rainure profonde

- Roulements à aiguilles

- Cylindrical Roller Bearings Full-Complement NCF

- Roulements à rouleaux coniques

- Roulements à rouleaux coniques

- Roulements à aiguilles

- Roulements à billes à contact angulaire

- Roulements à aiguilles

- Roulements à billes

- Roulements à billes à rainure profonde

- Thrust Spherical Roller Bearings Types TSR-EJ And TSR-EM

- Bola bantalan rol

- Bantalan gulung jarum

- Dorong bantalan bola

- Runcing roller bantalan

- Bantalan gulung jarum

- Bantalan bola kontak sudut

- Dalam alur bantalan bola

- Bola bantalan rol

- dorong roller bantalan

- Perumahan Bantalan

- Runcing Roller bantalan

- Bantalan biasa

- Dalam alur bantalan bola

- Bantalan bola untuk sudut

- Runcing Roller bantalan

- Runcing Roller bantalan

- Dalam alur bantalan bola

- Bantalan bola kontak sudut

- Dalam alur bantalan bola

- Bantalan Biasa

- Silinder Roller bantalan

- Bantalan perumahan

- Silinder Roller Bantalan

- Silinder Roller Bantalan

- Rolamentos de rolos cilíndricos de uma carreira

- Parker PAVC Piston Pump

- Rolamentos de rolos cônicos de duas filas de duas filas (série polegadas)

- Catálogo de rolamentos

- Rolamentos Complexos

- TDO Rolamentos de rolos cônicos de duas fileiras

- Rolamentos de esferas de impulso

- Rodamentos Cilíndricos De Rolo One-Row Metric ISO Series

- Rolamentos de esferas de contato angular

- Rolamento liso

- Vedações radiais de eixo

- Vickers Piston Pump

- Rolamentos de rolos cônicos de dupla linha interna dupla

- TOKYO-KEIKI Vane Pump

- Unidades de rolamentos

- Rolamentos de FAG

- Distribuidor de Rolamentos de Rolos Cilíndricos

- Rolamentos de rolos de impulso

- NACHI Piston Pump

- Rolamentos da unidade de cartucho

- Rolamento de rolos cilíndricos

- Радиальные шариковые подшипники

- Four Row Tapered Roller Bearings NTN

- Упорные роликовые подшипники

- Цилиндрические роликовые подшипники

- МОНТАЖНЫЕ УСТРОЙСТВА И ВСТАВКИ

- Double-Row Tapered Roller Bearings NSK

- Double Row Tapered Roller Bearings NTN

- Roll Bearings For Mills NSK

- ШАРИКОПОДШИПНИКИ

- Конические роликовые подшипники

- Конические роликоподшипники

- Вибрационный подшипники экрана

- Roller Bearings NSK

- SL Type Cylindrical Roller Bearings NTN

- Корпус подшипников

- подшипник

- Подшипниковые узлы

- Full-Complement Cylindrical Roller Bearings NSK

- Сферические подшипники скольжения и концы стержней

- Bearings For Special Applications NTN

- FOUR-ROW CYLINDRICAL ROLLER BEARINGS NSK

- Подшипники скольжения

- Tapered Roller Thrust Bearings For Adjusting Screws NSK

- Four Row Cylindrical Roller Bearings NTN

- Сферические роликовые подшипники

- Double-Row Tapered Roller Bearings NSK

- Многорядные роликовые подшипники NTN

- Double-Row Cylindrical Roller Bearings NSK

- Rolling Bearings For Steel Mills NSK

- Игольчатые роликоподшипники

- Самоустанавливающиеся шарикоподшипники

- Радиальные шариковые подшипники

- Single Row Tapered Roller Bearings NTN

- Радиально-упорные шарикоподшипники

- Цилиндрические роликовые подшипники

- шарикоподшипники

- Радиальные шариковые подшипники

- Конические роликовые подшипники

- Игольчатые роликоподшипники

- Crossed-Roller Bearings NSK

- Цилиндрические роликовые подшипники

- Spherical Roller Bearings NSK

- Подшипники скольжения

- Ball Bearings NSK

- SL Type Cylindrical Roller Bearings For Sheaves NTN

- Подшипниковый узел

- Sealed-Clean Four-Row Tapered Roller Bearings NSK

- Подшипниковые узлы

- Petroleum Machinery Bearing

- Oil Field Bearing

- Frac Pump Bearing

- Fracking Pump Bearings

- Mud Pump Crankshaft Bearing

- Oil Drilling Equipment Bearing

- Centrifugal Pump Bearings

- Mud Pump Bearing For Tesco Top Drive And Varco

- Rotary Table Bearings

- Petro Drill Bearing

- Self Aligning Ball Bearings

- Deep Groove Ball Bearings

- Company Profile

- Quality Control

- Contact Us

Home> Company News> Large Low-speed Rotary Bearing Fault Detection

- Product Groups

Four-Row Tapered Roller Bearings TQITS

(43)Nachi Gear Pump

(101)Four Row Tapered Roller Bearings

(647)TNASWH Two-Row Tapered Roller Bearings

(17)Cylindrical Roller Bearing

(3568)Tapered Roller Bearings Double-Row TNA

(85)Full Row Of Cylindrical Roller Bearings

(150)Four-Row Cylindrical Roller Bearing Inner Ring Outer Assembly

(130)Tapered Roller Bearings Double-Row Type TDO

(831)Vickers Gear Pump

(25)Four Row Cylindrical Roller Bearings NSK

(187)Oilfield Bearings

(1233)NSK Roll Bearings For Mills

(55)Thailand Bearing Authorized Dealer

(7997)Rolling Bearings For Steel Mills NSK

(526)NSK Double Row Tapered Roller Bearings

(110)NTN Multi-Row Roller Bearings

(232)TIMKEN Sealed Roll Neck Bearings

(188)Vickers Piston Pump

(586)Mud Pump Bearings

(625)TP Thrust Cylindrical Roller Bearing

(74)Slewing Ring

(7975)Tokyo Keiki Vane Pump

(641)Oilfield Bearings

(8751)Rexroth Pump

(909)Daikin Vane Pump

(108)Parker Vane Pump

(37)Thrust Bearings

(9988)Daikin Rotor Pump

(151)Maintenance Products Air Driven Oil Injector

(1490)Indonesia Bearing Authorized Dealer

(14193)Coupling Mounting And Dismounting Kit

(86)Singapore Bearing Authorized Dealer

(27614)Four-Row Cylindrical Roller Bearings

(164)Mud Oilfield Pump Bearings

(1354)TTHD Thrust Tapered Roller Bearings

(69)Double Row Cylindrical Roller Bearings

(578)Land Drilling Rig Bearing

(974)Heavy-Duty Needle Roller Bearings

(21)Heavy-Duty Shaker Screen Spherical Roller Bearings

(179)Four Row Cylindrical Roller Bearings NTN

(217)Spherical Roller Bearings NSK

(538)NSK Crossed Roller Bearings

(40)Single Row Tapered Roller Bearings Inch

(961)Tapered Roller Bearings Double-Row Spacer Assemblies

(952)Thrust Cylindrical Roller Bearings

(301)Thrust Spherical Roller Bearings

(115)Nachi Piston Pump

(339)Oil Industry Drilling Bearing

(11555)DTVL Angular Contact Thrust Ball Bearing

(15)Four Point Contact Ball Bearings

(176)Cylindrical Roller Thrust Bearing NSK

(45)Yuken Hydraulic Component

(739)Double Row Full Complement Cylindrical Roller Bearings

(162)Main Pump

(1266)Full-Complement NCF Cylindrical Roller Bearings

(38)Oilfield Mud Pump Bearings

(7000)Malaysia Bearing

(10003)NSK Single Direction Thrust Ball Bearings

(99)Oil Seal SKF

(2636)NSK Tapered Roller Thrust Bearing

(50)Single Row Cylindrical Roller Bearings

(394)Double Row Angular Contact Ball Bearings

(99)Thrust Spherical Roller Bearing

(67)Spherical Roller Bearing

(459)Deep Groove Ball Bearings

(226)Full Complement Tapered Roller Thrust Bearing

(36)Screwdown Systems Thrust Tapered Roller Bearings

(95)Cylindrical Roller Bearings One-Row Standrad Series

(80)FAG محامل

(8967)SKF محامل وحدات

(1664)محامل كروية من رولز NSK

(538)صف مزدوج تناقص الأسطوانة المحامل NSK

(110)محامل عادي SKF

(1805)SL Type أسطواني محامل ل شيفيس NTN

(23)فحوى الكرات

(201)فحوى الأسطوانة المحامل

(4518)الكرة الاخدود العميق محامل

(7830)المحامل الدفعية NSK

(46)محامل منتجات هندسية skf

(679)SKF محامل ختم

(3884)محامل متعددة الصف NTN

(232)رول محامل للمطاحن NSK

(55)المحامل الدفعية NTN

(279)اتجاه واحد الصدر محامل الكرة NSK

(99)محامل أسطوانية مزدوجة-رو NSK

(297)الكرة الاخدود العميق محامل

(7751)إبرة محامل

(7987)إبرة محامل

(7972)فحوى الكرات

(7998)محامل للتطبيقات الخاصة NTN

(182)SKF تحمل الملحقات

(1567)FAG محامل

(6329)محامل وحدات

(7997)محامل الإسكان

(1828)محامل حقول النفط

(631)محامل عادي

(3301)أربعة رو المحامل المدبب NSK

(76)الزاوي الاتصال الكرات

(7970)محامل القسم رقيقة KAYDON

(1729)محامل SKF

(3245)أربعة أسطواني محامل أسطواني NSK

(187)محامل اسطوانية أسطوانية NSK

(45)Rodamientos de agujas

(7983)Rodamientos

(7952)Rodamientos de una hilera de rodillos cónicos pulgadas

(961)Rodamientos de Bolas Autoalineables

(3148)Rodamientos de Rodillos Cilíndricos

(3850)Rodamientos de rodillos esféricos

(5346)Rodamientos de Rodillos Cilíndricos

(7591)Rodamientos de dos hileras de dos hileras de rodillos cónicos (serie de pulgadas)

(371)Unidades de rodamiento

(1826)Soportes para rodamientos

(3779)Parker PAVC Piston Pump

(344)Rexroth AA4VSO

(41)TDIK Rodamientos de rodillos

(78)Rodamientos de rodillos cónicos

(7922)Rodamientos de rodillos cónicos

(10206)Rodamientos de bolas de contacto angular

(7967)Rodamientos de dos hileras de bolas de contacto angular

(99)Rodamientos de dos hileras de rodillos cónicos dobles pulgadas

(497)Rodamientos de rodillos cónicos

(3164)Rodamientos de Rodillos Cilíndricos

(7284)Rodamientos de manga

(5285)Rodamientos de rodillos cónicos

(7536)Rodamientos de rodillos esféricos

(6)Rodamientos de agujas

(5514)Rodamiento de rodillos esféricos de empuje

(67)TTDFLK, TTDW And TTDK Rodamientos

(45)Rodamientos de Rodillos Cilíndricos

(8138)Completo rodillo cónico Rodamiento de empuje

(36)Rexroth A10VSO

(236)Rodamientos rígidos de bolas

(226)Accesorios Para Rodamientos

(1416)Rodamientos de bolas de precisión de precisión

(7736)Rodamientos de rodillos cónicos de doble hilera TDI TDIT

(294)Rodamientos de bolas de cuatro puntos de contacto

(176)Rodamientos dobles de dos hileras de rodillos cónicos TDI

(561)TOKYO-KEIKI Vane Pump

(641)Rodamientos de dos hileras de rodillos cónicos dobles

(250)Rodamientos de bolas de precisión

(3182)Sellos radiales de eje

(3781)Rodamientos de Rodillos Cilíndricos

(11511)Screwdown Systems Thrust Tapered Roller Bearings

(95)YUKEN Piston Pump

(278)SKF Unidades de rodamientos

(1825)Rodamientos de cuatro hileras de rodillos cónicos

(647)Rodamientos de una hilera de rodillos cónicos

(137)Rodamientos de equipos de fluidos de perforación

(625)DTVL Rodamiento de bolas de contacto angular

(15)Rodamientos de rodillos cilíndricos de empuje

(301)Parker PVP Piston Pump

(121)Unidades de rodamiento

(7998)Rodamientos de bolas de contacto angular

(322)Rodamientos De Bolas De Contacto Angular Type TVL

(27)TOKYO-KEIKI Piston Pump

(219)Rodamientos axiales de rodillos de empuje

(115)Rodamientos de agujas

(7976)Rodamientos Plásticos Plásticos

(3836)RODAMIENTOS PLÁSTICOS

(577)TDO Rodamientos de dos hileras de rodillos cónicos

(368)Rexroth A15VSO

(22)Rodamientos de agujas

(17)Roulements à billes à contact angulaire

(7791)Roulements à rouleaux cylindriques

(7889)Double-Row Tapered Roller Bearings NSK

(1035)TTHD Thrust Tapered Roller Bearings

(69)Roulements à rouleaux cylindriques

(7916)YUKEN Piston Pump

(293)Roulements à rouleaux cylindriques

(3573)TTHDFLSA Thrust Tapered Roller Bearings

(13)Roulements à billes à contact angulaire

(421)Roulements à rouleaux coniques

(8616)Roulements à aiguilles

(7823)Spherical Roller Bearings NSK

(538)Thrust Cylindrical Roller Bearings

(301)TTHDFL Thrust Tapered Roller Bearing

(65)Roulements à aiguilles

(7827)TPS Thrust Cylindrical Roller Bearing

(40)Four-Row Cylindrical Roller Bearings

(164)Roulements à rouleaux cylindriques

(7997)Roulements rigides à billes

(7976)unités de roulement

(499)Les roulements à rouleaux de confiance

(4514)Roulements à billes à contact angulaire

(7855)Heavy-Duty Needle Roller Bearings

(21)Roulements à billes

(7911)TP Thrust Cylindrical Roller Bearing

(74)Roulements à billes auto-alignés

(3158)Roulements à billes de poussée

(7990)Cylindrical Roller Bearings Two-Row

(96)Single-Row Tapered Roller Bearings NSK

(713)Roulements à billes à rainure profonde

(7874)Roulements à aiguilles

(7854)Roulements à rouleaux sphériques

(3368)Roulements à billes à rainure profonde

(7851)Roulements à billes à rainure profonde

(7775)Roulements à aiguilles

(8073)Cylindrical Roller Bearings Full-Complement NCF

(38)Roulements à rouleaux coniques

(7928)Roulements à rouleaux coniques

(7892)Roulements à aiguilles

(7989)Roulements à billes à contact angulaire

(7965)Roulements à aiguilles

(5649)Roulements à billes

(3381)Roulements à billes à rainure profonde

(774)Thrust Spherical Roller Bearings Types TSR-EJ And TSR-EM

(76)Bola bantalan rol

(7997)Bantalan gulung jarum

(7828)Dorong bantalan bola

(8198)Runcing roller bantalan

(8180)Bantalan gulung jarum

(9690)Bantalan bola kontak sudut

(7834)Dalam alur bantalan bola

(7765)Bola bantalan rol

(3351)dorong roller bantalan

(4516)Perumahan Bantalan

(1825)Runcing Roller bantalan

(7993)Bantalan biasa

(3298)Dalam alur bantalan bola

(7975)Bantalan bola untuk sudut

(7967)Runcing Roller bantalan

(7971)Runcing Roller bantalan

(7972)Dalam alur bantalan bola

(8558)Bantalan bola kontak sudut

(8230)Dalam alur bantalan bola

(7977)Bantalan Biasa

(7998)Silinder Roller bantalan

(7976)Bantalan perumahan

(7997)Silinder Roller Bantalan

(7229)Silinder Roller Bantalan

(12175)Rolamentos de rolos cilíndricos de uma carreira

(394)Parker PAVC Piston Pump

(344)Rolamentos de rolos cônicos de duas filas de duas filas (série polegadas)

(371)Catálogo de rolamentos

(7985)Rolamentos Complexos

(1036)TDO Rolamentos de rolos cônicos de duas fileiras

(368)Rolamentos de esferas de impulso

(8183)Rodamentos Cilíndricos De Rolo One-Row Metric ISO Series

(197)Rolamentos de esferas de contato angular

(7973)Rolamento liso

(3278)Vedações radiais de eixo

(3894)Vickers Piston Pump

(586)Rolamentos de rolos cônicos de dupla linha interna dupla

(497)TOKYO-KEIKI Vane Pump

(641)Unidades de rolamentos

(9717)Rolamentos de FAG

(4880)Distribuidor de Rolamentos de Rolos Cilíndricos

(7991)Rolamentos de rolos de impulso

(4527)NACHI Piston Pump

(339)Rolamentos da unidade de cartucho

(7999)Rolamento de rolos cilíndricos

(7998)Радиальные шариковые подшипники

(7972)Four Row Tapered Roller Bearings NTN

(308)Упорные роликовые подшипники

(12715)Цилиндрические роликовые подшипники

(8004)МОНТАЖНЫЕ УСТРОЙСТВА И ВСТАВКИ

(8400)Double-Row Tapered Roller Bearings NSK

(1035)Double Row Tapered Roller Bearings NTN

(720)Roll Bearings For Mills NSK

(55)ШАРИКОПОДШИПНИКИ

(7998)Конические роликовые подшипники

(476)Конические роликоподшипники

(7998)Вибрационный подшипники экрана

(211)Roller Bearings NSK

(68)SL Type Cylindrical Roller Bearings NTN

(76)Корпус подшипников

(7283)подшипник

(7990)Подшипниковые узлы

(7996)Full-Complement Cylindrical Roller Bearings NSK

(257)Сферические подшипники скольжения и концы стержней

(4012)Bearings For Special Applications NTN

(182)FOUR-ROW CYLINDRICAL ROLLER BEARINGS NSK

(187)Подшипники скольжения

(3300)Tapered Roller Thrust Bearings For Adjusting Screws NSK

(46)Four Row Cylindrical Roller Bearings NTN

(217)Сферические роликовые подшипники

(3354)Double-Row Tapered Roller Bearings NSK

(110)Многорядные роликовые подшипники NTN

(232)Double-Row Cylindrical Roller Bearings NSK

(297)Rolling Bearings For Steel Mills NSK

(526)Игольчатые роликоподшипники

(5536)Самоустанавливающиеся шарикоподшипники

(3148)Радиальные шариковые подшипники

(8531)Single Row Tapered Roller Bearings NTN

(256)Радиально-упорные шарикоподшипники

(8067)Цилиндрические роликовые подшипники

(3403)шарикоподшипники

(7997)Радиальные шариковые подшипники

(7981)Конические роликовые подшипники

(7992)Игольчатые роликоподшипники

(7995)Crossed-Roller Bearings NSK

(40)Цилиндрические роликовые подшипники

(8002)Spherical Roller Bearings NSK

(538)Подшипники скольжения

(7998)Ball Bearings NSK

(233)SL Type Cylindrical Roller Bearings For Sheaves NTN

(23)Подшипниковый узел

(8402)Sealed-Clean Four-Row Tapered Roller Bearings NSK

(76)Подшипниковые узлы

(1825)Petroleum Machinery Bearing

(110)Oil Field Bearing

(150)Frac Pump Bearing

(290)Fracking Pump Bearings

(220)Mud Pump Crankshaft Bearing

(157)Oil Drilling Equipment Bearing

(84)Centrifugal Pump Bearings

(90)Mud Pump Bearing For Tesco Top Drive And Varco

(70)Rotary Table Bearings

(60)Petro Drill Bearing

(100)Self Aligning Ball Bearings

(57)Deep Groove Ball Bearings

(58)

Large Low-speed Rotary Bearing Fault Detection

2018-08-28 21:00:04There are a lot of testing techniques for slewing bearing barrier,mainly including vibration detection, iron spectrum analysis and light spectrum analysis.

However,the straight diameter of the shaft bearing reaches 5.4m, the rotation speed is gr /m I n, the rotation frequency of the rolling body is lower than that of 1 H z. The inner and outer ring of the shaft bearing and the characteristic frequency of the rolling body can not be collected through the common speedup sensor, and the lateral dynamic test square is not suitable for the diagnosis of the fault of the shaft bearing.And iron spectrum and light spectrum detection technology can pass through the sampling points, grease the wear state of slewing bearing, diagnostic axis bearing is disabled, for slewing bearing for further technology in accordance with the repairs According to the shaft bearing type belongs to the low speed heavy load, by using the extreme pressure 1 file matrix embellish smooth, embellish grease viscosity is relatively large, poor flow dynamic and its in the grinding damage of micro particle distribution is very uneven, to overcome the grinding in the grease samplesThe appearance of uneven distribution of grain distribution, in addition to the number of added lipids, also correct

Three iron spectra were made for each lipid sample and three primary emission optical subdivisions were conducted to separate the oil samples from the old shantou in the inner and outer ring of the shaft bearing.

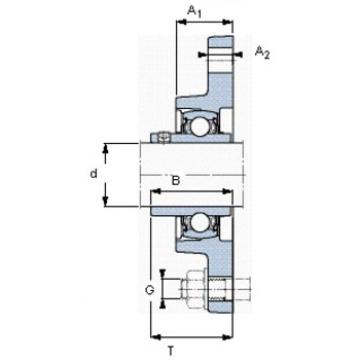

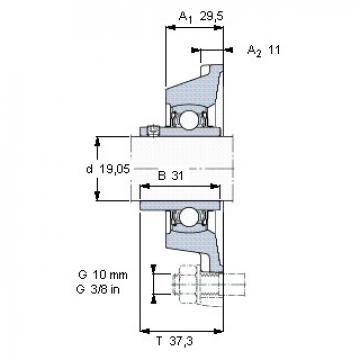

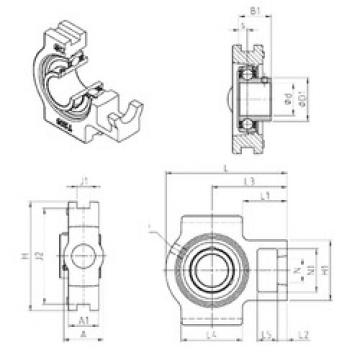

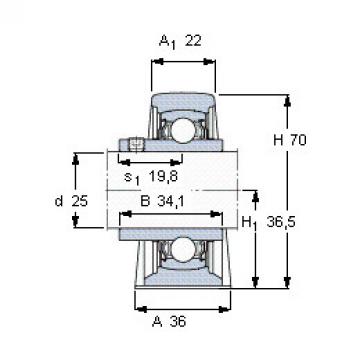

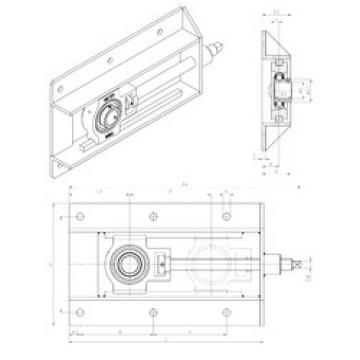

Подшипник YAR 204-2FW/VA228 SKF

Подшипник YAR 204-2FW/VA228 SKF Подшипник YAR 204-012-2FW/VA201 SKF

Подшипник YAR 204-012-2FW/VA201 SKF Подшипник UST210 SNR

Подшипник UST210 SNR Подшипник YAR 205-2FW/VA228 SKF

Подшипник YAR 205-2FW/VA228 SKF Подшипник UST210+WB SNR

Подшипник UST210+WB SNR